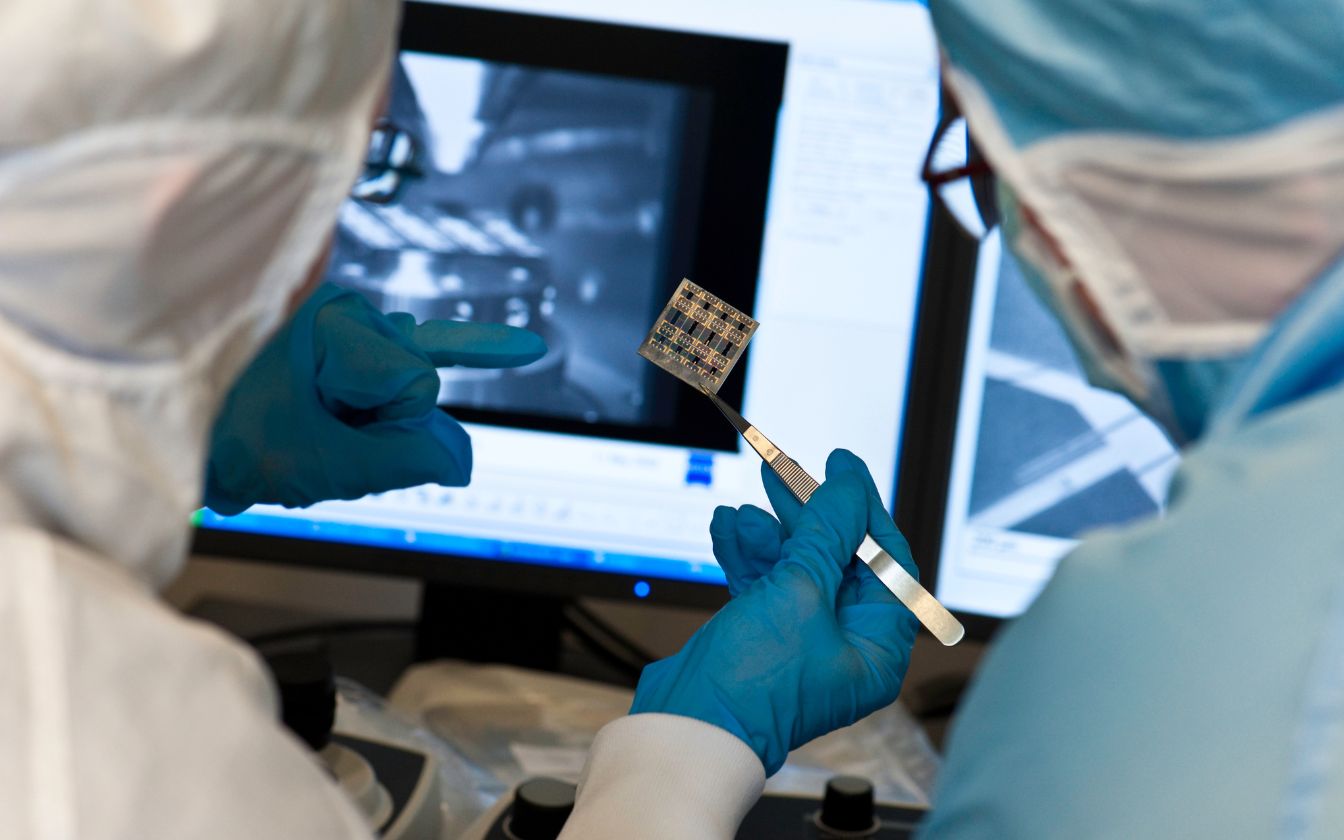

Clean rooms

Cleanrooms enable the production of microelements that are 10–100 times smaller than the diameter of a strand of hair. These microelements are at the heart of complex systems: sensors for the urban environment, neural implants for functional rehabilitation in the cerebral cortex and retina, and connected objects.

Equipment and methods

Training

Research

Industrial partnerships

3 missions in synergy missions…

Training

Training accounts for 5-10 % of activity. Per year, around 250 students are trained / taught in the cleanrooms of institutions in the Ile-de-France region. ESIEE Paris is the regional training centre for micro-technologies.

Research

20-30 % of activity in cleanrooms is dedicated to research, which is associated with the ESYCOM laboratory, UMR CNRS 9007.

Business

Supporting businesses accounts for two-thirds of our activity. This is either through the hosting of full-time placement engineers to the platform, in order to carry out their research and development and manufacture small series, or even through services provided by the platform team.

Various application sectors

Environment and sustainable cities Health and biomedicalAerospace and defence Optical communications Energy

Discover the new cleanrooms on video!

Key figures

650 m²

Surface in class ISO 5 and ISO 7

> 70

Heavy equipment (electron microscope, deep silicon etching, photolithography, etc.)

5

Startups created in 10 years

250 à 300

Students per year

ESIEE Paris benefits from the support of the CNRS within the national RENATECH+ network and several other large-scale projects that are funded by the PIA (Programme for Future Investments), such as the EquipEx ‘Sense-City - Nanosensors for Sustainable Cities’ (PIA1) and the EquipEx+ ‘NANOFUTUR’ (PIA3).

The Microelectronics and Microsystems Department (SMM) team

Sales Department

The Technological Processes Department team

Infrastructure & Safety / Maintenance Division